Limited Time 30% Discount Offer Use Code - off30

Actualkey Prepration Latest MB-335 : Microsoft Dynamics 365 Supply Chain Management Functional Consultant Expert Exam Questions and Answers PDF's, Verified Answers via Experts - Pass Your Exam For Sure and instant Downloads - "Money Back Guarantee".

| Vendor | Microsoft |

| Certification | Microsoft 365 |

| Exam Code | MB-335 |

| Title | Microsoft Dynamics 365 Supply Chain Management Functional Consultant Expert Exam |

| No Of Questions | 152 |

| Last Updated | August 20,2024 |

| Product Type | Q & A with Explanation |

| Bundel Pack Included | PDF + Offline / Andriod Testing Engine and Simulator |

Candidates for this exam are expert or senior supply chain functional consultants who implement and configure advanced features of Dynamics 365 Supply Chain Management to meet the requirements of a business. They have an advanced knowledge of supply chain management operations, including production, logistics, master planning, and asset management. The candidate will identify use cases for applying mixed reality.

Candidates analyze business requirements and translate those requirements into fully realized business processes and solutions and apply industry-recommended practices to implementations.

Candidates demonstrate expertise in one or more of the following manufacturing methods: discrete, process, and lean. The candidate partners with architects, developers, consultants, and other stakeholders to implement solutions that meet or exceed the needs of their customers.

Exam MB-335: Microsoft Dynamics 365 Supply Chain Management Functional Consultant Expert

Languages: English

Retirement date: none

This exam measures your ability to accomplish the following technical tasks: configure products; configure production prerequisites; implement production methods; configure production control; and describe and implement additional supply chain management features.

Skills measured

Review the study guide linked in the preceding “Tip” box for more details about the skills measured on this exam.

Configure products (15–20%)

Configure production prerequisites (20–25%)

Implement production methods (15–20%)

Configure production control (20–25%)

Describe and implement additional supply chain management features (10–15%)

About the exam Languages

Some exams are localized into other languages. You can find these in the Schedule Exam section of the Exam Details webpage. If the exam isn’t available in your preferred language, you can request an additional 30 minutes to complete the exam.

Note

The bullets that follow each of the skills measured are intended to illustrate how we are assessing that skill. Related topics may be covered in the exam.

Note

Most questions cover features that are general availability (GA). The exam may contain questions on Preview features if those features are commonly used.

Skills measured

Audience profile

Candidates for this exam are expert or senior supply chain functional consultants who implement and configure advanced features of Dynamics 365 Supply Chain Management to meet the requirements of a business. They have an advanced knowledge of supply chain management operations including production, logistics, master planning, and asset management. The candidate will identify use cases for applying mixed reality.

Candidates analyze business requirements and translate those requirements into fully realized business processes and solutions and applies industry-recommended practices to implementations.

Candidates demonstrate expertise in one or more of the following manufacturing methods: discrete, process, and lean. The candidate partners with architects, developers, consultants, and other stakeholders to implement solutions that meet or exceed the needs of their customers.

Configure products (15-20%)

Configure production prerequisites (20-25%)

Implement production methods (15-20%)

Configure production control (20-25%)

Describe and implement additional supply chain management features (10-15%)

Configure products (15–20%)

Implement product information for production

Configure planning items, co-products, and by-products for batch orders

Configure catch weight handling policies

Configure inventory batches, batch attributes, and lot inheritance

Manage product compliance including regulated and restricted items

Define configuration groups and routes for dimension-based products

Manage products with dimension-based, constraint-based, and pre-defined variants

Configure bills of materials (BOMs), formulas, and routes to manage scrap

Implement Product Configurator for Dynamics 365

Create and manage product configuration model components and subcomponents

Create calculations for product configuration models

Differentiate between table and expression constraints

Configure BOM lines and route operations for a product configuration model

Configure and manage pricing for configuration models

Describe the purpose and capabilities of the product configurator

Validate, approve, and test product configuration models

Implement Engineering Change Management

Design an engineering product lifecycle

Configure engineering categories

Configure product readiness policies and product release policies

Create an engineering product with engineering attributes

Review and accept released products to a local company

Add engineering products to a sales order, purchase orders and production orders

Schedule and implement engineering change requests and change orders

Configure production prerequisites (20-25%)

Configure resources, routes, and calendars

Implement and manage work calendars and working time

Create and configure resource capabilities

Implement and manage resources and resource groups

Create and manage operations and routes

Configure production settings and processes

Create production units, production groups, production pools, and production journal names

Describe integration between general ledger and production control modules

Manage reservations in production process, including partial reservations and re-reservations

Configure warehouse processes for raw materials picking and finished goods put away

Describe unified (mixed mode) manufacturing

Configure production control parameters

Describe production and batch order process statuses

Implement costing

Configure costing sheets and indirect costs

Configure and manage cost groups, costing versions, and cost categories

Configure cost allocations for co-products and burden allocation for by-products

Configure and perform BOM/formula calculations

Activate item prices

Describe production posting profiles

Describe common sources of production variances

View and analyze production and inventory costs

Implement production methods (15–20%)

Implement discrete manufacturing

Create BOM and item configurations

Create and process production orders

Create and process picking list journals

Create and process job card and route card journals

Create and process reports as finished journals

Reset the status of a production order

Describe use cases and configure production-related reservations

Implement process manufacturing

Configure batch reservations and release to warehouse process

Configure consolidated batch order processes

Manage batch balancing and batch order sequencing

Configure formulas features

Create and process report as finished journals with co-products and by-products

Create and process batch orders and a rework batch order

Create formulas and formula versions

Implement lean manufacturing

Create value streams and production flows

Configure production flow costing

Create kanban rules

Process kanban orders by using kanban boards

Create and manage fixed, scheduled, and event kanbans

Configure production control (20–25%)

Implement subcontracting

Describe use cases for subcontracting processes

Implement activity-based subcontracting

Configure BOM and formula lines, resources, and routes for subcontracting items

Create service items for subcontracting

Create and process subcontracting purchase orders

Implement manufacturing execution

Configure time and attendance prerequisites and activate workers for time registration

Identify the capabilities of manufacturing execution

Process production and batch orders by using manufacturing execution processes

Configure production floor execution interface and job card terminals

Calculate and approve time registrations

Implement advanced master planning scenarios

Process and view planned orders

Configure intercompany master planning

Configure forecast models and parameters

Run demand forecasting and adjust as appropriate

Execute explosion and validate results

Describe how supply chain calendars affect master planning

Implement production scheduling and capacity planning

Define scheduling parameters

View, monitor, and update production schedules

Configure capacity for production resources including machines, labor, and tooling

Describe infinite and finite scheduling and capacity

Describe differences between operations and job scheduling

Describe and implement additional supply chain management features (10–15%)

Describe cloud and edge scale units

Describe the value proposition for scale units for warehouse workloads

Describe warehouse management processes that can run on a scale unit

Describe manufacturing processes that can run on a scale unit

Describe use cases for integrating mixed reality technologies with Dynamics 365 Supply Chain Management

Describe use cases for Dynamics 365 Guides

Describe the process for integrating mixed reality Dynamics 365 Guides with manufacturing processes

Describe the process for integrating mixed reality Dynamics 365 Guides with asset management

Implement Asset Management

Configure maintenance plans

Configure functional locations

Manage maintenance requests

Manage work orders consumption

Manage work order scheduling

QUESTION 1

You need to configure costing for raw materials used to manufacture unscented cleaning solution.

Which form should you use?

A. Cost basis type

B. Quantity and margin template

C. Pricing calculation

D. Pricing template

Answer: B

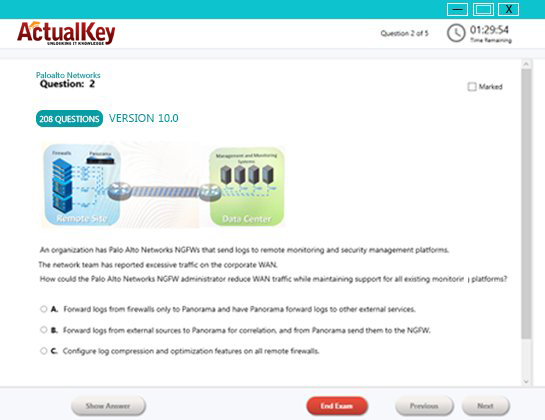

QUESTION 2

You need to configure production control parameters for liquid cleaning solution manufacturing.

What are two possible ways to achieve this goal? Each correct answer presents a complete solution.

NOTE: Each correct selection is worth one point.

A. Require an electronic signature when the formula is approved.

B. Select Block editing and approve the formula.

C. Select the Block removal of approval option for the formula

D. Select the Block editing option only.

Answer: BC

QUESTION 3

You need to configure production operations for the pine and orange scent solutions.

Which three actions should you perform? Each correct answer presents part of the solution.

NOTE: Each correct selection is worth one point.

A. Configure the inventory policy for the item model group to set the value of the Stocked product option to Yes.

B. Use a purchase agreement as a service agreement.

C. Allocate subcontracted work in its own cost breakdown block.

D. Configure a costing resource and requirement to point to a Vendor type resource.

E. Configure the BOM line to be of type Vendor and associate the corresponding vendor account.

Answer: C, D, E

I Got My Success Due To Actualkey MB-335 Bundle Pack Actualkey experts I got passed in the MB-335 exam without any worries at all, these exam material products gave me the reason to relax.

Budi Saptarmat

Yahoo! Got Successfully Through The MB-335 Exam Passing Exam is not a easy thanks to Acutalkey.com for providing me actual MB-335 Microsoft Dynamics 365 Supply Chain Management Functional Consultant Expert Exam training with there included the Offline and Android simulators helps me success

Melinda

MB-335 Exam Best Preparation I have been preparing for MB-335 Microsoft Dynamics 365 Supply Chain Management Functional Consultant Expert Exam, I was not sure that I'll be able to pass because of the fact that I am not a good student however;Actualkey.com provided me best and simple exam training pdf's and I passed. I now recommend everyone

Antonio Moreno

Actualkey.com MB-335 Offline Simulator is Best My choice to select Actualkey.com and go for the preparation MB-335 Microsoft Dynamics 365 Supply Chain Management Functional Consultant Expert Exam, because I got the short way with the easy way

Liliane Meichner

Actualkey.com MB-335 Exam PDF"s passed with in a week MB-335 exam pdf's that's amazing

James Wilson

Microsoft - RELATED EXAMS

Designing a Database Server Infrastructure by Using Microsoft SQL Server 2005

Questions: 92 Questions | September 16, 2024

Optimizing and Maintaining a Database Administration Solution by Using SQL Server 2005

Questions: 215 | September 16, 2024

UPGRADE: MCDBA Skills to MCITP Database Administrator by Using Microsoft SQL Server 2005

Questions: 186 Questions | September 16, 2024

Microsoft .NET Framework 2.0 - Windows-Based Client Development

Questions: 245 Questions | September 16, 2024

Microsoft .NET Framework 2.0 - Distributed Application Development

Questions: 144 | September 16, 2024

Microsoft .NET Framework 2.0-Application Development Foundation

Questions: 456 | September 16, 2024

Designing and Developing Web-Based Applications by Using the Microsoft .NET Framework

Questions: 74 | September 16, 2024

Designing and Developing Windows-Based Applications by Using the Microsoft .NET Framework

Questions: 72 Questions | September 16, 2024

Designing and Developing Enterprise Applications by Using the Microsoft .NET Framework

Questions: 86 | September 16, 2024

UPGRADE: MCAD Skills to MCPD Web Developer by Using the Microsoft .NET Framework

Questions: 584 | September 16, 2024

UPGRADE: MCAD Skills to MCPD Windows Developer by Using the Microsoft .NET Framework

Questions: 559 | September 16, 2024

UPGRADE: MCSD Microsoft .NET Skills to MCPD Enterprise Application Developer: Part 1

Questions: 609 | September 16, 2024

UPGRADE: MCSD Microsoft .NET Skills to MCPD Enterprise Application Developer: Part 2

Questions: 168 | September 16, 2024

TS: Deploying and Maintaining Windows Vista Client and 2007 Microsoft Office System Desktops

Questions: 92 | September 16, 2024

Windows Server 2008 Applications Infrastructure, Configuring

Questions: 494 | September 16, 2024

TS: Upgrading from Windows Server 2003 MCSA to, Windows Server 2008, Technology Specializations

Questions: 576 | September 16, 2024

Designing a Microsoft Office Enterprise Project Management (EPM) Solution

Questions: 50 Questions | September 16, 2024

Customizing Portal Solutions with Microsoft SharePoint Products and Technologies

Questions: 75 | September 16, 2024

Deploying Business Desktops with Microsoft Windows Server 2003 and Microsoft Office 2003

Questions: 53 | September 16, 2024

Implementing and Administering Security in a Microsoft Windows Server 2003 Network

Questions: 288 | September 16, 2024

Designing, Deploying, and Managing a Network Solution for a Small- and Medium-Sized Business

Questions: 204 | September 16, 2024

Supporting Users and Troubleshooting a Microsoft Windows XP Operating System

Questions: 114 | September 16, 2024

TS: Microsoft SQL Server 2008, Business Intelligence Development and Maintenance

Questions: 399 | September 16, 2024

PRO: Designing, Optimizing and Maintaining a Database Administrative Solution Using Microsoft SQL Server 2008

Questions: 189 | September 16, 2024

Developing E-Business Solutions Using Microsoft BizTalk Server 2004

Questions: 40 | September 16, 2024

Developing Microsoft Office Solutions Using XML with Office Professional Edition 2003

Questions: 50 | September 16, 2024

Planning and Building a Messaging and Collaboration Environment Using Microsoft Office System and Microsoft Windows Server 2003

Questions: 61 | September 16, 2024

TS: Microsoft .NET Framework 3.5, ADO.NET Application Development

Questions: 287 | September 16, 2024

TS: Microsoft .NET Framework 3.5, ASP.NET Application Development

Questions: 364 | September 16, 2024

TS: Microsoft Office Project Server 2007, Managing Projects

Questions: 145 | September 16, 2024

TS: Microsoft .NET Framework 3.5, Windows Forms Application Development

Questions: 48 | September 16, 2024

Upgrade: Transition Your MCITP SQL Server 2005 DBA to MCITP SQL Server 2008

Questions: 98 | September 16, 2024

Pro: Designing and Deploying Messaging Solutions with Microsoft Exchange Server 2010

Questions: 379 | July 1, 2024

Pro: Designing and Developing ASP.NET Applications Using the Microsoft .NET Framework 3.5

Questions: 281 | September 16, 2024

TS: Microsoft SQL Server 2008, Implementation and Maintenance

Questions: 328 | September 16, 2024

Microsoft System Center Configuration Manager 2007,Configuring

Questions: 184 | September 16, 2024

PRO: Designing and Developing Microsoft SharePoint 2010 Applications

Questions: 200 | September 16, 2024

Upgrading to Windows 7 MCITP Enterprise Desktop Support Technician

Questions: 50 | September 16, 2024

TS: Windows Applications Development with Microsoft .NET Framework 4

Questions: 278 | September 16, 2024

TS: Windows Communication Foundation Development with Microsoft .NET Framework 4

Questions: 473 | September 16, 2024

TS: Web Applications Development with Microsoft .NET Framework 4

Questions: 405 | September 16, 2024

Pro: Designing and Developing Web Applications Using Microsoft .NET Framework 4

Questions: 288 | September 16, 2024

TS: Developing Business Process and Integration Solutions by Using Microsoft BizTalk Server 2010

Questions: 100 | September 16, 2024

Designing and Providing Microsoft Volume Licensing Solutions to Small and Medium Organizations

Questions: 232 | September 16, 2024

TS: Forefront Protection for Endpoints and Applications, Configuring

Questions: 105 | September 16, 2024

Upgrade: Transition Your MCITP SQL Server 2005 DBD to MCITP SQL Server 2008 DBD

Questions: 154 | July 1, 2024

Pro: Windows Server 2008 R2, Virtualization Administrator

Questions: 176 | September 16, 2024

PRO: Designing Database Solutions and Data Access Using Microsoft SQL Server 2008

Questions: 183 | July 1, 2024

Managing and Maintaining a Microsoft Windows Server 2003 Environment

Questions: 450 | July 1, 2024

Implementing Data Models and Reports with Microsoft SQL Server 2012

Questions: 330 | July 1, 2024

Implementing a Data Warehouse with Microsoft SQL Server 2012

Questions: 322 | September 16, 2024

Transition Your MCTS on SQL Server 2008 to MCSA: SQL Server 2012, Part 2

Questions: 300 | September 16, 2024

Configuring and Deploying a Private Cloud with System Center 2012

Questions: 462 | September 16, 2024

Monitoring and Operating a Private Cloud with System Center 2012

Questions: 457 | September 16, 2024

Administering and Deploying System Center 2012 Configuration Manager

Questions: 208 | September 16, 2024

Microsoft Dynamics AX 2012 Process Manufacturing Production and Logistics

Questions: 149 | July 1, 2024

Advanced Metro style App Development using HTML5 and JavaScript

Questions: 225 | September 16, 2024

Transition Your MCTS on SQL Server 2008 to MCSA: SQL Server 2012, Part 1

Questions: 230 | September 16, 2024

Transition Your MCITP: Database Administrator 2008 or MCITP: Database Developer 2008 to MCSE: Data Platform

Questions: 261 | September 16, 2024

Transition Your MCITP: Business Intelligence Developer 2008 to MCSE: Business Intelligence

Questions: 132 | September 16, 2024

Designing Database Solutions for Microsoft SQL Server 2012

Questions: 231 | September 16, 2024

Designing Business Intelligence Solutions with Microsoft SQL Server 2012 Exam

Questions: 314 | September 16, 2024

Microsoft Programming in HTML5 with JavaScript and CSS3 Exam

Questions: 342 | September 16, 2024

Delivering Continuous Value with Visual Studio 2012 Application Lifecycle Management

Questions: 219 | July 1, 2024

Enterprise Voice & Online Services with Microsoft Lync Server 2013

Questions: 158 | September 16, 2024

Developing Microsoft SharePoint Server 2013 Core Solutions

Questions: 181 | September 16, 2024

Upgrade your MCPD: Web Developer 4 to MCSD: Web Applications

Questions: 229 | September 16, 2024

Essentials of Developing Windows Metro style Apps using C#

Questions: 168 | September 16, 2024

Server Virtualization with Windows Server Hyper-V and System Center

Questions: 149 | September 16, 2024

Essentials of Developing Windows Metro style Apps using HTML5 and JavaScript

Questions: 166 | September 16, 2024

TS: Windows Small Business Server 2011 Standard, Configuring

Questions: 55 | September 16, 2024

TS: MS Internet Security & Acceleration Server 2006, Configuring

Questions: 80 | September 16, 2024

TS: Microsoft System Center Operations Manager 2007, Configuring

Questions: 94 | September 16, 2024

TS: System Center Virtual Machine Manager 2008, Configuring

Questions: 45 | September 16, 2024

PRO: Designing a Business Intelligence Infrastructure Using Microsoft SQL Server 2008

Questions: 115 | September 16, 2024

Upgrade: Transition Your MCITP SQL Server 2005 BI Developer to MCITP SQL Server 2008 BI Developer

Questions: 203 | September 16, 2024

Recertification for MCSD: Application Lifecycle Management

Questions: 292 | September 16, 2024

TS: Microsoft .NET Framework 3.5 Windows Presentation Foundation Application Development

Questions: 101 | September 16, 2024

TS: Microsoft .NET Framework 3.5 - Windows Communication Foundation

Questions: 270 | September 16, 2024

TS: Visual Studio Team Foundation Server 2010, Administration

Questions: 72 | September 16, 2024

Pro: Designing and Developing Windows Applications Using Microsoft .NET Framework 4

Questions: 239 | September 16, 2024

TS: Microsoft Windows SharePoint Services 3.0 Application Development

Questions: 109 | September 16, 2024

Upgrade: Transition your MCPD Enterprise Application Developer Skills to MCPD Enterprise Application Developer 3.5, Part 1

Questions: 153 | September 16, 2024

UPGRADE: Transition your MCPD Enterprise Application Developer Skills to MCPD Enterprise Application Developer 3.5, Part 2

Questions: 123 | September 16, 2024

TS: System Center Data Protection Manager 2007, Configuring

Questions: 74 | September 16, 2024

Designing and Providing Microsoft Volume Licensing Solutions to Large Organizations

Questions: 126 | September 16, 2024

TS: Designing, Assessing, and Optimizing Software Asset Management (SAM)

Questions: 85 | September 16, 2024

MS Office Communication Server 2007-U.C Voice Specialization

Questions: 174 | September 16, 2024

Microsoft Office Communications Server 2007 R2 U.C. Voice Specialization

Questions: 101 | September 16, 2024

Windows Server 2008 Hosted Environments, Configuring and Managing

Questions: 75 | September 16, 2024

Designing and Providing Microsoft Volume Licensing Solutions to Large Organisations

Questions: 104 | September 16, 2024

Pro: Designing and Developing Windows Applications Using the Microsoft .NET Framework 3.5

Questions: 105 | July 1, 2024

Pro: Designing and Developing Enterprise Applications Using the Microsoft .NET Framework 3.5

Questions: 152 | September 16, 2024

Universal Windows Platform – App Data, Services, and Coding Patterns (beta)

Questions: 47 | September 16, 2024

Universal Windows Platform – App Architecture and UX/UI (beta)

Questions: 76 | September 16, 2024

Microsoft Dynamics AX 2012 R3 CU8 Installation and Configuration

Questions: 48 | July 1, 2024

Designing and Deploying Microsoft Exchange Server 2016 Exam

Questions: 166 | September 16, 2024

Introduction to Programming Using Block-Based Languages (Touch Develop)

Questions: 72 | July 1, 2024

Development, Extensions and Deployment for Microsoft Dynamics 365 for Finance and Operations

Questions: 90 | July 1, 2024

Financial Management in Microsoft Dynamics 365 for Finance and Operations

Questions: 73 | July 1, 2024

Designing and Providing Microsoft Licensing Solutions to Large Organizations

Questions: 195 | July 1, 2024

Distribution and Trade in Microsoft Dynamics 365 for Finance and Operations

Questions: 93 | July 1, 2024

Administering Microsoft System Center Configuration Manager and Cloud Services Integration

Questions: 150 | July 1, 2024

Microsoft Configuring and Operating a Hybrid Cloud with Microsoft Azure Stack Exam

Questions: 99 | July 1, 2024

Microsoft Azure Solutions Architect Certification Transition Exam

Questions: 393 | July 1, 2024

Outlook 2016: Core Communication, Collaboration and Email Skills

Questions: 35 | July 1, 2024

Microsoft Developing Solutions for Microsoft Azure Exam

Questions: 170 / 6 Case Study | July 1, 2024

Designing and Implementing a Data Science Solution on Azure Exam

Questions: 442 | December 3, 2024

Microsoft 365 Teamwork Administrator Certification Transition Exam

Questions: 120 | July 1, 2024

Microsoft Messaging Administrator Certification Transition Exam

Questions: 155 | July 1, 2024

Microsoft Excel 2016: Core Data Analysis, Manipulation, and Presentation Exam

Questions: 35 | November 8, 2024

Microsoft Word 2016: Core Document Creation, Collaboration and Communication Exam

Questions: 35 | November 8, 2024

Microsoft Dynamics 365 for Finance and Operations, Supply Chain Management Exam

Questions: 394 | November 25, 2024

Microsoft Dynamics 365 for Finance and Operations, Manufacturing Exam

Questions: 207 | November 8, 2024

Building Applications and Solutions with Microsoft 365 Core Services Exam

Questions: 242 | July 1, 2024

Microsoft Dynamics 365: Finance and Operations Apps Solution Architect Exam

Questions: 295 | February 18, 2025

Planning and Administering Microsoft Azure for SAP Workloads Exam

Questions: 652 | July 1, 2024

Microsoft Dynamics 365: Finance and Operations Apps Developer Exam

Questions: 283 | February 21, 2025

Administering Relational Databases on Microsoft Azure (beta) Exam

Questions: 341 | December 13, 2024

Microsoft Dynamics 365 Business Central Functional Consultant (beta) Exam

Questions: 196 | March 8, 2025

Microsoft Power Platform Functional Consultant (beta) Exam

Questions: 289 | February 18, 2025

Configuring and Operating a Hybrid Cloud with Microsoft Azure Stack Hub Exam

Questions: 176 | July 1, 2024

Microsoft Dynamics 365 Fundamentals Customer Engagement Apps (CRM) (beta) Exam

Questions: 159 | October 12, 2024

Microsoft Dynamics 365 Fundamentals Finance and Operations Apps (ERP) Exam

Questions: 146 | February 14, 2025

Configuring and Operating Windows Virtual Desktop on Microsoft Azure Exam

Questions: 207 | February 20, 2025

Designing and Implementing a Microsoft Azure AI Solution (beta) Exam

Questions: 321 | December 2, 2024

Designing and Implementing Microsoft Azure Networking Solutions Exam

Questions: 294 | March 1, 2025

Designing Microsoft Azure Infrastructure Solutions (beta) Exam

Questions: 324 | January 16, 2025

Designing and Implementing Cloud-Native Applications Using Microsoft Azure Cosmos DB (beta) Exam

Questions: 140 | January 28, 2025

Configuring Windows Server Hybrid Advanced Services (beta) Exam

Questions: 157 | October 22, 2024

Administering Windows Server Hybrid Core Infrastructure (beta) Exam

Questions: 334 | September 2, 2024

Microsoft Designing and Implementing Enterprise-Scale Analytics Solutions Using Microsoft Azure and Microsoft Power BI Exam

Questions: 160 | July 1, 2024

Microsoft Dynamics 365 Supply Chain Management Functional Consultant Expert Exam

Questions: 152 | August 20, 2024

Implementing Analytics Solutions Using Microsoft Fabric Exam

Questions: 117 | February 21, 2025

Implementing Data Engineering Solutions Using Microsoft Fabric Exam

Questions: 67 | January 9, 2025

Exams code, certifications, vendor or keywords

![]()

Copyright © 2009 - 2025 Actualkey. All rights reserved.